Die-closingSwager

Torrington die-closing (DC) swagers are used to make diameter reductions on rods, heavy tubes and assembliess such as aircraft control cables which cannot be swaged with the standard swagers. The DC machine enables the workpiece to be placed in the machine in a predetermined position and swaged anywhere on it without starting from an end.

OperatingPrinciple

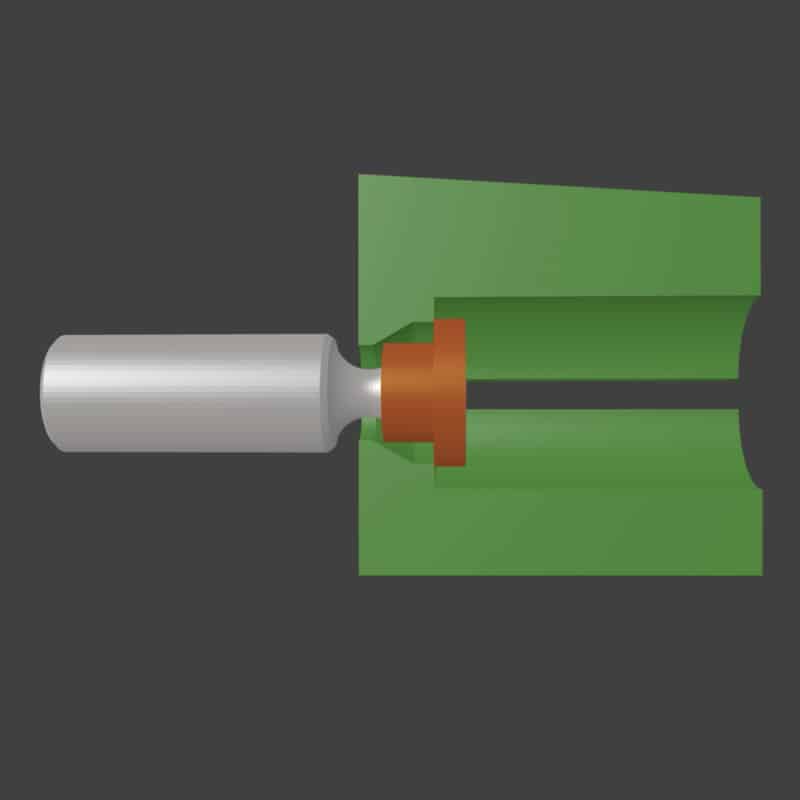

The animation shows the mechanism of a die-closing swager. It is essentially a rotary swager with an added wedge mechanism that allows the dies to open wider. The wedge system is moved by a hydraulic system. These machines are unique to Torrington and have been developed to expand the swaging possibilities. The animation illustrates the following process:

- The wedge starts in its retracted position to allow maximum spacing between the swaging dies and material insertion in the machine

- The wedge advances axially, closing the dies enough to hold the part in place without swaging.

- At that point, the spindle starts rotating and the wedge closes the dies together, effectively forming the material.

- Once the wedge reaches its full stroke, the spindle’s rotation is stopped, the wedge retracts to fully open the dies and the formed part is removed.

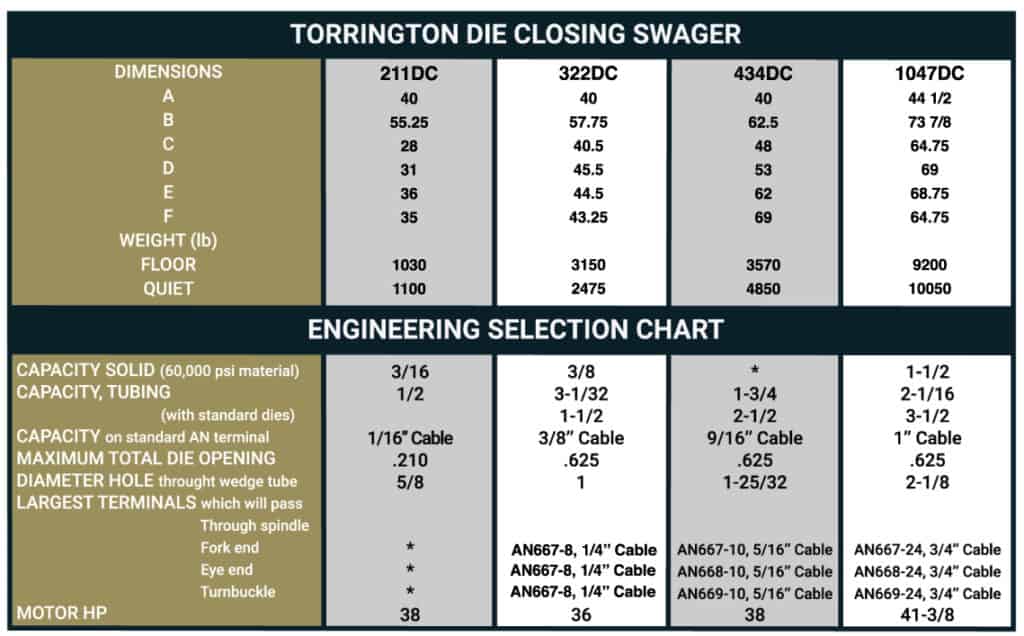

MachineSpecifications

Multipleapplications

Whether you need mechanical assemblies, MS/AN fittings or specific reduction positions, Torrington’s die-closing swagers stand ready to help:

- Reductions with specific positioning

- Piston assemblies for hydraulic motors, ensuring a perfect spherical joint

- Cable end assemblies, as replacement for welded components in hostile environments encountered in naval and aircraft industries